Imtex Membranes is currently in the process of commercializing Permylene, an innovative membrane technology for efficient olefin-paraffin separation. Suited for C2 to C4 applications, Imtex is exploring a wide range of applications by working closely with industry leading technology and operating companies.

Permylene™ membrane technology is receiving significant interest from multinational petrochemical companies for C4 applications as an alternative method of separating butenes from butanes. This is currently achieved predominantly via traditional distillation and, for some isomers, solvent extraction (eg. butadiene). There exists a wide range of C4 applications, characterized by the various feed concentrations and product requirements.

Separating C4s can be more complex than for lighter molecules such as ethylene and propylene, primarily due to the wider range of isomers and similar boiling points. Olefin isomers range from 1-butene, cis-2-butene, trans-2-butene and isobutene with butadiene often a consideration as well. Each form possesses different properties that are advantageous as the building blocks for many materials and applications. 1-butene for example is used as a co-monomer for some types of polyolefin, while butadiene is used in the manufacture of synthetic rubber. The properties of 2-butene make it ideal for metathesis feed for the on-purpose production of propylene.

C4 mixtures are often a form of raffinate, a byproduct stream from primary refinery and petrochemical processes, hence the wide range of concentrations and feed compositions. Each application needs to be reviewed on its own details, basis and requirements. The preferential permeation of some isomers versus others may be of interest in applications where the C4 mixture composition can be altered to favour certain isomers.

C4s are well suited to Permylene technology due to high olefin permeation rates and the moderate temperatures/pressures required for vaporizing and liquefying C4 as required. This enables improved membrane efficiency (by area) and simpler integration as high pressure differentials are not required.

Some examples of C4 applications for Permylene consideration include:

- Extracting value from C4 raffinate streams

- Monomer extraction/recovery; targeting specific isomers such as 1-butene

- Metathesis feed where 2-butene is preferential

- Alkylation; targeting 1-butene for controlled feed composition

- Specialty applications requiring specific feed compositions

- Extracting value from by- product C4 streams e.g. FCC.

- Butene removal to purify paraffin streams

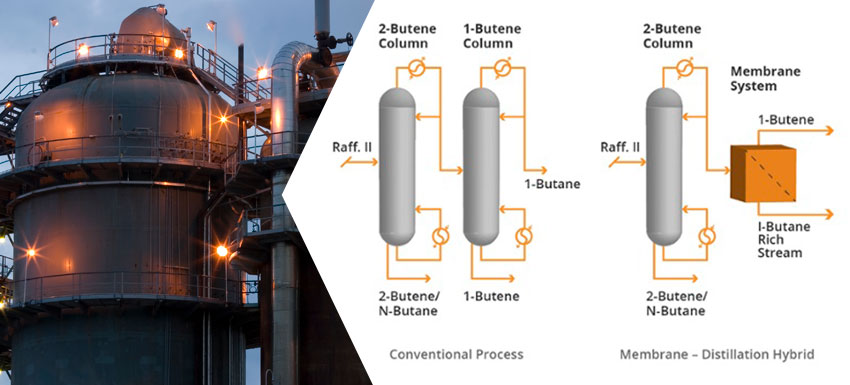

It’s important to note that Permylene’s primary function is to separate olefins from paraffins. While a degree of preferential permeation of isomers exists, if olefin isomers are to be purified, a distillation hybrid design may be required such as the one shown in (Case Study: 1-Butene Purification from C4 Raffinate). This hybrid system is still more cost effective and efficient than a typical mutli-stage distillation system.

Contaminants have to be considered for the Permylene system; however these would normally need to be removed to achieve product purity specifications in any case. Imtex Membranes has worked with numerous technology licensors in order to identify suitable pretreatment technologies and process design concepts.

Due to the unique characteristics of petrochemical plants, olefin streams and subsequent Permylene applications, the merits of each opportunity need to be assessed based on their specific details. For more information or to discuss any applications you have in mind, please contact us.